Effective Workplace Safety with Lockout/Tagout Equipment

When it comes to ensuring the safety of your employees and the integrity of your industrial equipment, lockout/tagout measures should be your top priority. With the use of specialized Lockout and Tagout (LOTO) equipment such as the non-conductive and non-sparking individually keyed Safety Lockout Padlock, industrial facilities can minimize the risk of hazardous energy-related accidents during maintenance or repair.

Why Lockout/Tagout Matters

Lockout/Tagout procedures refer to the lockout and tagging of all energy sources that power machines or equipment in the workplace. These procedures help prevent unexpected start-up or release of stored energy that can potentially cause physical harm to workers. According to data from the Occupational Safety and Health Administration (OSHA), removing or bypassing lockout/tagout measures is one of the top ten most frequently cited OSHA violations in industries such as manufacturing, construction, and even service establishments.

Applying Lockout/Tagout Measures

When employees are assigned to work on equipment or machines, lockout/tagout measures must be applied to ensure that they are safe from hazardous energy sources. LOTO equipment is used to lock the energy source in its “off” position to prevent activation of the equipment while work is being done. Tags and labels are used to identify the energy source that has been locked out or de-energized.

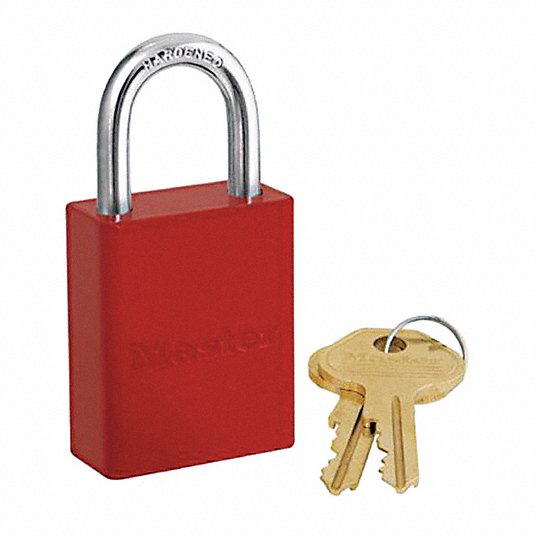

Common LOTO equipment includes padlocks, hasps, valve lockouts, cable lockouts, circuit breaker lockouts, and other specialized devices that fit specific energy sources. A padlock like the Orange non-conductive non-sparking Safety Lockout Padlock is perfect for locking out electrical switches, valves, and other energy sources that need to be deactivated during maintenance or repair.

The Significance of LOTO Procedures

The importance of applying lockout/tagout procedures in the workplace cannot be overemphasized. Lockout/tagout measures help protect workers from potential harm caused by unexpected start-up or release of stored energy in machines and equipment. These measures also help prevent accidents such as cuts, fractures, electrocution, and even fatalities because of unsafe working conditions.

More so, LOTO procedures are necessary for complying with OSHA’s standards and ensuring the safety of your workers. Industrial facilities are mandated by OSHA to have lockout/tagout procedures in place and to provide proper training on these procedures to their employees.

Final Thoughts

The importance of lockout/tagout procedures in ensuring the safety of workers and protecting the integrity of industrial equipment cannot be overstated. With the use of LOTO equipment such as the Orange non-conductive non-sparking Safety Lockout Padlock, industrial facilities can minimize the risk of hazardous energy-related accidents during maintenance or repair. If your workplace needs LOTO solutions, call our Manchester based office for more information on our different lockout/tagout products.